The Classification And Processing Of Brass

Lead is actually insoluble in brass and is distributed on the grain boundary in the state of free particles. Lead brass has two types: α and (α+β) according to its organization. Alpha lead brass can only be cold-deformed or hot-extruded due to the harmful effects of lead and low high-temperature plasticity. (α+β) Lead brass has good plasticity at high temperature and can be forged.

The addition of tin to brass can significantly improve the heat resistance of the alloy, especially the ability to resist seawater corrosion, so tin brass is called “navy brass”.

Tin can dissolve into copper-based solid solution and play a role in solid solution strengthening. However, with the increase of tin content, brittle r-phase (CuZnSn compound) will appear in the alloy, which is not conducive to the plastic deformation of the alloy. Therefore, the tin content of tin brass is generally in the range of 0.5% to 1.5%.

Commonly used tin brass are HSn70-1, HSn62-1, HSn60-1 and so on. The former is an alpha alloy, which has high plasticity and can be processed by cold and hot pressure. The alloys of the latter two grades have a (α+β) two-phase structure, and a small amount of r-phase often appears. The room temperature plasticity is not high, and they can only be deformed in a hot state.

Manganese has greater solubility in solid brass. Adding 1% to 4% manganese to brass can significantly improve the strength and corrosion resistance of the alloy without reducing its plasticity.

Manganese brass has a (α+β) structure, and HMn58-2 is commonly used. The pressure processing performance in cold and hot states is quite good.

In iron brass, iron is precipitated as iron-rich particles, which serve as crystal nuclei to refine the grains, and can prevent the growth of recrystallized grains, thereby improving the mechanical properties and process performance of the alloy. The iron content in iron brass is usually less than 1.5%, and its structure is (α+β), which has high strength and toughness, good plasticity at high temperature, and can be deformed in cold state. The commonly used grade is Hfe59-1-1.

Nickel and copper can form a continuous solid solution, significantly expanding the α phase region. The addition of nickel to brass can significantly improve the corrosion resistance of brass in the atmosphere and seawater. Nickel also increases the recrystallization temperature of brass, promoting the formation of finer grains.

HNi65-5 nickel brass has a single-phase α structure, good plasticity at room temperature, and can also be deformed in a hot state, but the content of impurity lead must be strictly controlled, otherwise it will seriously deteriorate the hot workability of the alloy.

The purity of brass can be measured by Archimedes’ principle, the volume and mass of the sample can be measured, and then the proportion of copper contained in brass can be calculated according to the density of copper and the density of zinc.

It is an alloy composed of copper and zinc.

When the zinc content is less than 35%, zinc can dissolve in copper to form single-phase a, called single-phase brass, which has good plasticity and is suitable for hot and cold press processing.

When the zinc content is 36%~46%, there is a single phase and a β solid solution based on copper and zinc, which is called dual-phase brass. The β phase reduces the plasticity of brass and increases the tensile strength, which is only suitable for Hot pressure processing.

If the mass fraction of zinc continues to increase, the tensile strength will decrease and it will have no use value.

The code is represented by “H + number”, H represents brass, and the number represents the mass fraction of copper.

For example, H68 means brass with a copper content of 68% and a zinc content of 32%. For cast brass, add the word “Z” before the code, such as ZH62.

For example, Zcuzn38 means cast brass with a zinc content of 38% and copper as the balance.

H90 and H80 belong to single-phase brass, golden yellow, so they are called gold, which are called plating, decorations, medals, etc.

H68 and H59 belong to duplex brass, which are widely used in structural parts of electrical appliances, such as bolts, nuts, washers, springs, etc.

In general, single-phase brass for cold deformation processing and dual-phase brass for hot deformation processing.

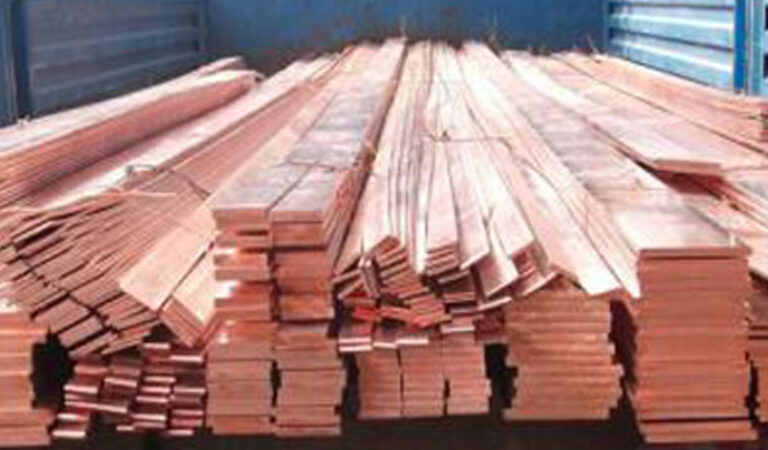

A multi-component alloy composed of other alloying elements added to ordinary brass is called brass. Commonly added elements are lead, tin, aluminum, etc., which can be called lead brass, tin brass, and aluminum brass accordingly. The purpose of adding alloying elements. Mainly to improve the tensile strength and improve the manufacturability.

Code: It is expressed as “H + main addition element symbol (except zinc) + copper mass fraction + main addition element mass fraction + other element mass fraction”.

Such as: HPb59-1 means that the mass fraction of copper is 59%, the mass fraction of the main element lead is 1%, and the balance is lead brass with zinc.

The hot working temperature is 750-830°C; the annealing temperature is 520-650°C; the low-temperature annealing temperature for eliminating internal stress is 260-270°C.

Environmentally friendly brass C26000 C2600 Excellent plasticity, high strength, good machinability, welding, good corrosion resistance, heat exchangers, paper tubes, machinery, electronic parts.

Specifications (mm): Specifications: thickness: 0.01-2.0mm, width: 2-600mm;

Hardness: O, 1/2H, 3/4H, H, EH, SH, etc.;

Applicable standards: GB, JISH, DIN, ASTM, EN;

Features: Excellent cutting performance Suitable for high-precision parts processed by automatic lathes and CNC lathes. [2]