your brass

cnc machining parts,We care

As a Top Custom CNC Machining Parts Manufacturer and Brass CNC Machining Service Provider, Pintejin Has Established Long-term Cooperation with Lots of Customers All Around the World with Its High Quality, Innovative Technologies, and Favorable Prices.

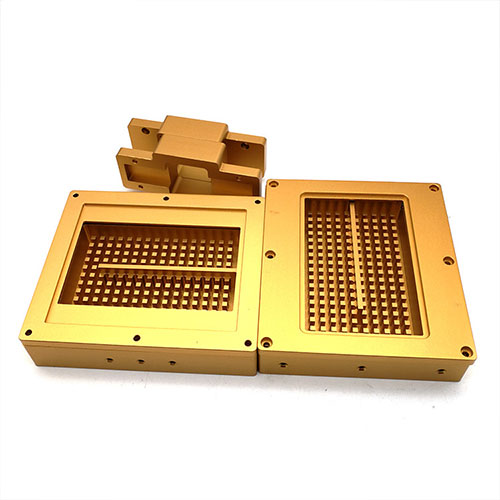

cnc milling brass

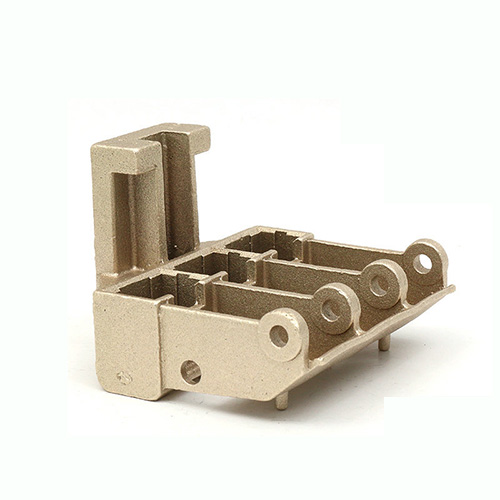

cnc turning brass

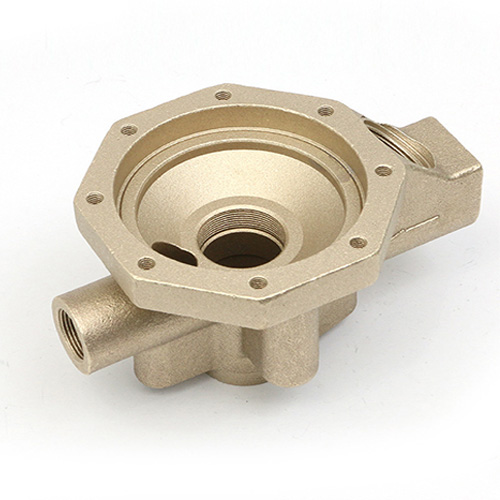

SWISS MACHINING BRASS

OUR BRASS MACHINED CAPABILITIES

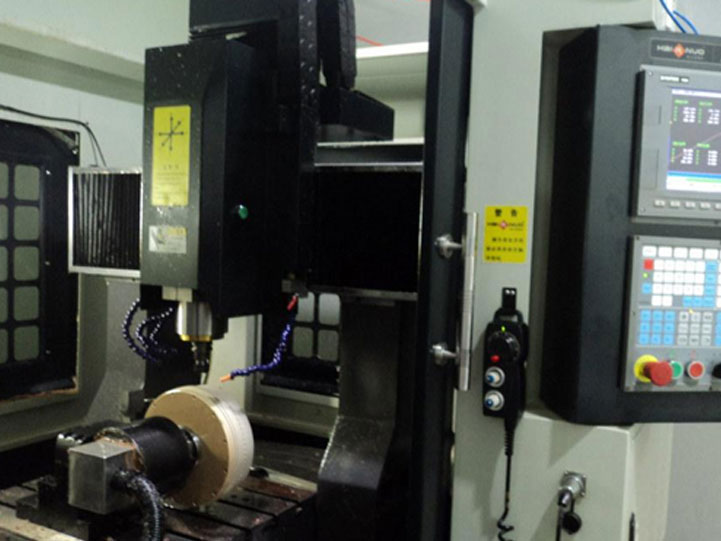

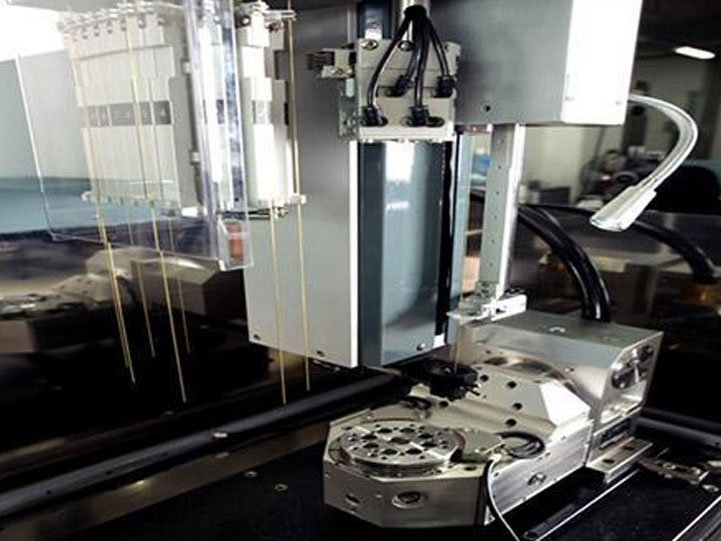

Pintejin is a recognized and trusted brass cnc machining partner in many industries around the world and has established good strategic partnerships with a lot of well-known companies both in China and around the world. Compared with other brass CNC service providers, Pintejin has great advantages to meet your requirements in terms of technology, quality, and price. With the support of Pintejin’s professional experience and technologies, many partners have achieved their ideas, and this puts Pintejin’s custom brass parts further ahead of other brass machining service companies in fields such as aerospace, military, medicine, and communication. Now Pintejin is using this solid foundation to explore a larger global market. In order to meet high-quality requirements in various industries around the world, Pintejin has purchased the best CNC milling machines and screw machines from Germany, the best CNC lathes from Switzerland, and the best high-precision 5 axis machine and testing equipment from Japan.

the RFQS of brass cnc machined

PLEASE REFER TO THE ANSWERS TO THE QUESTIONS ASKED THE MOST.

brass CNC machining serviceS & mANUFACTURER

Established nearly 30 years ago, Dongguan pintejin group is your professional customized brass machining parts supplier in China, which has been pursuing high precision brass parts manufacturing including brass CNC turning parts, brass CNC milling parts, brass casting parts as well as non-standard brass parts, with a production pass rate of 99.9%.

Pintejin’s precision brass machining factory covers an area of 30000 square meters, with a production capacity of 20 million pieces per month. For an urgent order, we can produce a high-precision sample within 24 hours. For Pintejin’s brass parts manufacturing, we can manufacture a new mold within 5 days and provide a sample within 7 days.

Now we have CNC 3-axis, 4-axis, and 5-axis high-speed 700T stamping equipment, die-casting equipment, high-precision screw machines, and cold heading machines, and we are always in pursuit of technological breakthroughs and training talents. Call or email us now, and we will immediately provide you with 24-hour professional brass cnc machining services and professional machining cooperation.

Choose the fastest route to ensure that we can always deliver the goods to you one step ahead

We have the ability to customize machining parts in large quantities and provide perfect after-sales service

Professional quotation within 24 hours, give us your drawings, and make prototypes quickly

Without your consent, 100% protect your privacy, do not reveal your personal address, be safe and secure

Choose the fastest route to ensure that we can always deliver the goods to you one step ahead

bEST brass machining parts

All of our brass machined components are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.If you require a well-established and cost-effective brass CNC machining company to take over your project, Pintejin can achieve your expectation.